Full automatic hot dipped galvanized machine

Galvanized Wire specification:1.6 ~ 4.0mm

Tensile strength:low carbon 450 N/mm2 ~ 550 N/mm2

Zinc layer thickness:galvanized 40~80/150~ 300 g/m2 zinc aluminum 150~ 300 g/m2

008615075178660

admin@steelwiremachine.com

Galvanized Wire specification:1.6 ~ 4.0mm

Tensile strength:low carbon 450 N/mm2 ~ 550 N/mm2

Zinc layer thickness:galvanized 40~80/150~ 300 g/m2 zinc aluminum 150~ 300 g/m2

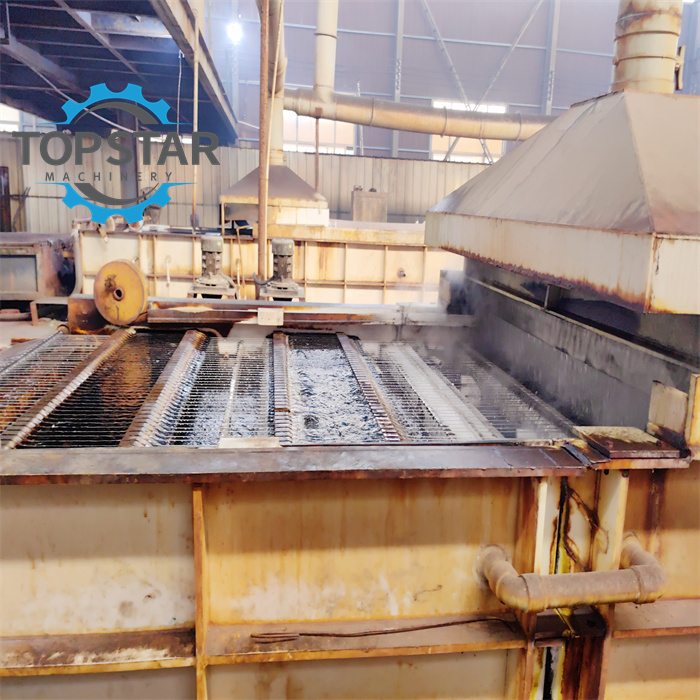

Full automatic hot dipped galvanized machine heavy galvanized galfan wire production line can be finished in one production line with different technology.

Full automatic hot dipped galvanized machine Main Feature:

1) Simple structure in linear type ,easy in installation and maintain.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Much less power and energy consumption

4) Favourable price and mature hand over system

5) Rich experience of equipment improvement and development

6) Easy operation and centralized control of take up

Full automatic hot dipped galvanized machine procedure is as below:

The H wheel of pay-off — gas pipe annealing heat treatment– – air cooled — tasteless pickling —plating assistant-dry the wire — hot dip galvanized steel wire pan— Coating wiping—water cool after hot dipped galvanized—air cool after hot dipped galvanized —wire collection

Full automatic hot dipped galvanized machine Specification

| Low-carbon steel wire | According to the standard of hot-dip galvanizing and zinc-aluminum alloy for low-carbon steel wire. |

| Product specifications | 1.6 ~ 4.0mm |

| Tensile strength | low carbon 450 N/mm2 ~ 550 N/mm2 |

| Zinc layer thickness | galvanized 40~80/150~ 300 g/m2 zinc aluminum 150~ 300 g/m2 |

| Production speed | D / V40 ~ 60 (maximum 80) |

| The number of steel wire | 24 |

| Steel wire spacing | pre-treatment 35mm; zinc 45mm |

| The length of the production line tooling | U-shaped structure about 140m |

| Heating energy | mixed gas or converter gas, electric energy |

| Power requirements | ~ 380V, 50Hz(customized) |